Performance made easy

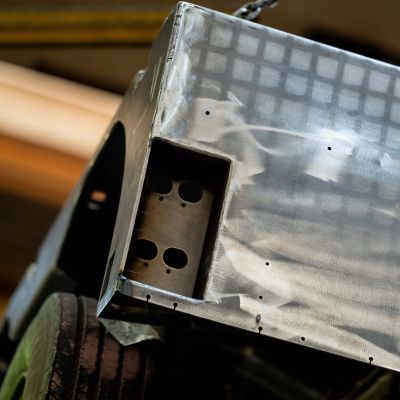

The foundations for top performance are laid in our factory. All our vehicles are built in our professional, precise and careful production process. We pay special attention to the stability of the frame and all components, to achieving a perfect finish, and to the long-term strength of our products. We only use high-quality materials – such as long-lasting fine-grained steel – in our production process. We also deploy automated production techniques and robot technology. Man and machine in perfect harmony – our guiding principle in production and out on the road.

Our mission to be one step ahead

In our research and development department, 35 engineers create intelligent details and complete solutions for the vehicles of tomorrow – driven by the mission of being one step ahead.

Worldwide.

How can we help you? Describe your service or emergency concerns on the 24-hour service hotline: